Harnessing Bacterial Magnetosomes for Eco-Friendly Wastewater Cleanup

Magnetic Bacteria:

Bioremediation has long been a cornerstone of sustainable environmental management, providing nature-based solutions to tackle a wide range of pollutants without the need for highly toxic chemical treatments. Traditionally, this field has been dominated by microbial and enzymatic methods, using bacteria, fungi, and enzymes to degrade hazardous substances into harmless by-products. In recent years, innovations have expanded the bioremediation toolkit to include genetic engineering, synthetic biology, and advanced monitoring systems.

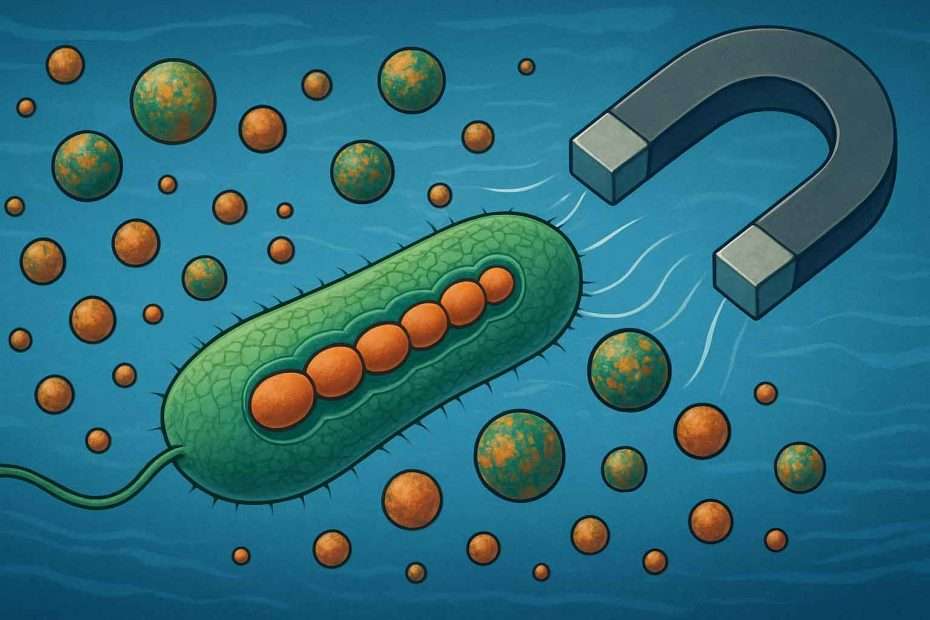

Yet one of the most exciting and lesser-known developments lies at the intersection of microbiology and nanotechnology: the use of magnetotactic bacteria and their naturally occurring magnetic nanoparticles—known as magnetosomes—to clean up polluted water. This approach offers a promising fusion of biological efficiency and physical retrievability, potentially transforming how industries and municipalities handle contamination. Magnetotactic bacteria are a diverse group of microorganisms that have evolved to produce intracellular, nanometre-scale crystals of magnetic minerals, typically magnetite (Fe₃O₄) or greigite (Fe₃S₄). These crystals are enveloped in a lipid membrane, forming what are collectively known as magnetosomes.

Arranged in chains within the bacterial cell, magnetosomes act like tiny compass needles, aligning the bacterium with the Earth’s magnetic field. In nature, this helps them navigate towards optimal environments, often microaerophilic zones in aquatic sediments where oxygen levels are low but not absent. In the laboratory and in applied settings, these magnetosomes present an extraordinary opportunity: they can bind to pollutants such as heavy metals, dyes, pesticides, and even radioactive isotopes, and can then be physically retrieved from water using magnetic separation.

This means that unlike conventional microbial bioremediation, where microorganisms may remain in the treated water or die and release their contents back into the environment, magnetotactic bacteria offer a built-in recovery mechanism. Once the pollutant-laden bacteria are captured using an external magnet, they can be removed entirely from the system, ensuring complete extraction of the contaminants. The environmental problem this technology seeks to address is immense. Industrial wastewater, mining runoff, pesticide contamination, and urban effluents contribute to a growing global crisis of water pollution. Many conventional treatment methods are expensive, generate toxic sludge, or are energy-intensive. By contrast, magnetotactic bacteria are self-replicating, operate at ambient temperatures, and require relatively simple nutrient inputs to thrive.

Their magnetosomes, owing to their nanoscale size and crystalline perfection, have exceptionally high surface area-to-volume ratios, allowing them to bind pollutants effectively. Laboratory studies have demonstrated impressive removal efficiencies: for example, certain strains can sequester over 90% of lead, cadmium, and arsenic from contaminated water within hours. Similar results have been reported for synthetic dyes and organic pollutants, with magnetosomes acting as adsorptive hotspots. One of the most compelling aspects of magnetosome-based remediation is reusability. Once the bacteria are magnetically separated from the water, the bound pollutants can be desorbed or chemically stripped from the magnetosomes, allowing the nanoparticles to be redeployed in subsequent treatment cycles. This closed-loop approach aligns strongly with the principles of the circular economy, minimising waste and reducing the need for continuous production of new remediation agents.

In some cases, even the recovered pollutants have residual value: heavy metals, once purified, can be recycled into industrial processes, adding an economic incentive to the environmental benefit. For BioGlobe, a company already positioned at the forefront of enzyme-driven remediation, the potential for synergy is striking. Enzymatic methods excel at breaking down complex organic molecules, such as petroleum hydrocarbons, pesticides, and industrial chemicals, into less harmful components. Magnetotactic bacteria, meanwhile, offer a more direct physical removal route for inorganic and persistent pollutants. Integrating these methods could lead to hybrid systems in which enzymes degrade organic contaminants into smaller, more manageable fragments, which are then bound and removed by magnetosomes. Such a system could handle mixed-pollutant scenarios that often occur in real-world wastewater streams, for example, in textile manufacturing effluents containing both synthetic dyes and heavy metals, or in agricultural runoff laced with pesticides and fertiliser residues.

The technology is not without its challenges. Cultivating magnetotactic bacteria at industrial scales is more complex than growing common bioremediation strains like Pseudomonas or Bacillus. Magnetotactic bacteria have specific oxygen requirements, often thriving only in microaerophilic or anaerobic zones. Maintaining these conditions in large-scale bioreactors or open water environments can be technically demanding. Additionally, while magnetosomes are inherently biocompatible, introducing live bacteria into open ecosystems raises regulatory and ecological considerations. Strategies to mitigate these issues include using harvested magnetosomes rather than live cells, or engineering non-magnetotactic, easy-to-cultivate bacteria to produce magnetosome-like particles. Advances in synthetic biology have already made it possible to transfer magnetosome-forming gene clusters into more robust host species, paving the way for scalable production without the ecological risks of live magnetotactic bacteria releases. From a sustainability standpoint, magnetosome-based remediation offers multiple advantages over conventional treatments. The low energy requirements of bacterial growth, the potential for pollutant recovery and recycling, and the avoidance of toxic sludge all contribute to its environmental credentials.

Moreover, the process can be fine-tuned for specific pollutants by functionalising magnetosome surfaces with binding ligands, enzymes, or other reactive groups, thereby expanding their range of targets. For example, magnetosomes could be coated with enzymes to break down oil hydrocarbons while simultaneously binding heavy metals—turning each nanoparticle into a multifunctional remediation unit. Case studies in recent years highlight the growing interest in this approach. In China, pilot projects have tested magnetosome-assisted removal of arsenic from groundwater in mining regions, achieving compliance with drinking water standards in fewer treatment cycles than traditional methods.

In Europe, research teams have used magnetosomes to remove radioactive isotopes from nuclear power plant wastewater, demonstrating that the particles retain their magnetic and structural integrity even under high radiation exposure. In Japan, a collaborative project has explored using magnetosomes to clean up microplastic pollution, exploiting the particles’ ability to adsorb hydrophobic compounds and then be magnetically extracted. These early successes point to a wide range of potential applications beyond wastewater treatment, including soil remediation, air filtration, and even medical detoxification therapies. The economic implications are equally promising.

While initial R&D and cultivation infrastructure can be costly, operational expenses tend to be low once the system is running, particularly if magnetosomes are reused multiple times. For industries facing strict regulatory limits on effluent discharge, the technology could offer a cost-effective route to compliance. Additionally, the prospect of recovering valuable metals from waste streams could turn pollution control from a cost centre into a revenue source. Mining companies, for instance, could deploy magnetosome-based systems not only to prevent contamination but also to capture and recycle trace metals that would otherwise be lost. Integrating magnetosome technology into BioGlobe’s portfolio would require careful planning. R&D could focus on optimising hybrid treatments, where enzyme formulations pre-treat organic matter before magnetosome application.

Pilot projects could target sectors with complex wastewater profiles—such as food processing plants, chemical manufacturers, and ports dealing with bilge water—demonstrating both environmental and economic returns. Public outreach would also be critical; explaining the natural origin of magnetosomes and their benign nature could help counter misconceptions about “nano” technologies and genetically engineered organisms. Looking to the future, the most exciting prospect is a fully integrated, modular bioremediation system in which different biological and physical components are deployed in sequence or in parallel, depending on the pollutant load. Imagine a wastewater treatment line where enzymes, microbes, magnetosomes, and perhaps even AI-controlled biosensors work together to achieve near-total decontamination in a single pass. Such systems could be mobile and containerised for deployment in disaster zones or remote communities, or permanently installed in urban treatment plants.

The adaptability and scalability of magnetosome technology make it well-suited to this vision. In the context of global environmental policy, adopting magnetosome-based bioremediation could help countries meet water quality targets under frameworks such as the UN Sustainable Development Goals (SDGs), particularly SDG 6 on clean water and sanitation, and SDG 12 on responsible consumption and production. Furthermore, because magnetosome production can be decentralised—using local bioreactors near the point of need—the technology lends itself to community-level engagement and capacity-building. In summary, magnetotactic bacteria and their magnetosomes represent an innovative, eco-friendly, and highly adaptable approach to pollution control. Their ability to bind and remove pollutants with magnetic precision offers a unique complement to existing enzyme-driven strategies, opening the door to powerful hybrid solutions for some of the most intractable environmental challenges.

For BioGlobe, incorporating this technology could reinforce its position as a leader in sustainable remediation, enhance its technical capabilities, and expand its market reach into new industrial sectors. The path forward will require investment, interdisciplinary collaboration, and continued public education, but the potential rewards—in cleaner water, recovered resources, and restored ecosystems—are substantial. As industries and governments alike grapple with the urgent need for effective and sustainable pollution control, magnetic bacteria may well prove to be the unexpected heroes of the next environmental revolution.

Bioglobe offer Enzyme pollution remediation for major oil-spills, oceans and coastal waters, marinas and inland water, sewage and nitrate remediation and also agriculture and brown-field sites, globally.

For further information:

BioGlobe LTD (UK),

22 Highfield Street,

Leicester LE2 1AB

Phone: +44(0) 116 4736303| Email: info@bioglobe.co.uk