Blending enzymes with wetlands and data

Smarter catchments

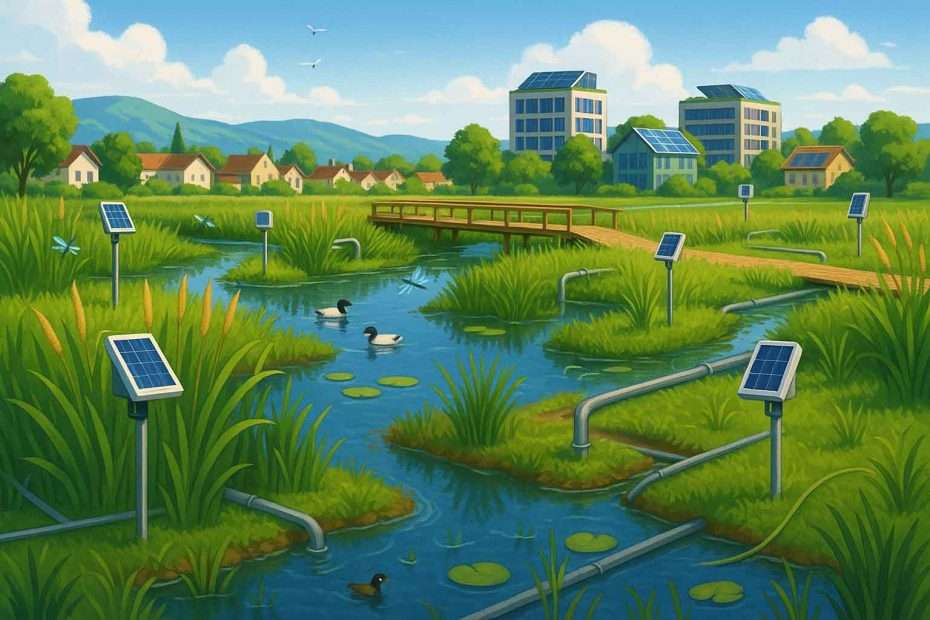

Modern stormwater and wastewater systems are being pushed to their limits by climate volatility, urban densification, ageing assets and evolving environmental standards. Water companies and councils face a stark reality: conventional “grey” infrastructure alone cannot keep pace with episodic extremes, rising nutrient loads, and surges of organics that drive combined sewer overflow (CSO) events and downstream water quality failures. Yet there is a practical, affordable way forward: a smarter catchment approach that fuses living systems (wetlands, reedbeds, green corridors) with biochemical interventions (e.g., enzyme dosing and bioaugmentation) and real‑time monitoring and control. This article sets out a blueprint in UK English for utilities and local authorities to deploy such integrated solutions, reduce CSO loads, cut nutrients and organics, and deliver improved resilience and lower lifecycle costs.

The proposal is not to discard traditional engineering methods; rather, it is to squeeze more value from existing assets and spaces by orchestrating them as a system. Nature‑based solutions (NBS) provide passive, resilient treatment and storage; enzyme and microbial tools accelerate biodegradation where it matters most; and a layer of sensors, analytics, and automation makes all components work together to deliver measurable outcomes.

What follows is a comprehensive guide to the technical rationale, system architecture, deployment roadmap, economics, risk management, and governance required to make “smarter catchments” a mainstream reality.

1. Why smarter catchments now?

1.1 The challenge in brief

- Climate intensification: Longer dry spells followed by intense convective storms generate first‑flush pollution, hydraulic shocks and higher CSO frequency.

- Asset fatigue: Many UK combined systems, culverts and pumping stations are decades old and were not designed for today’s urban loads or rainfall patterns.

- Nutrients and organics: Diffuse and point sources of nitrogen, phosphorus, biochemical oxygen demand (BOD) and chemical oxygen demand (COD) degrade receiving waters, undermine biodiversity and breach targets.

- Affordability pressure: Customers demand better performance without bill shocks; regulators require demonstrated improvements and transparency; councils juggle constrained budgets and competing priorities.

- Space constraints: Urban retrofit faces land and planning pressures, limiting the scope for large end‑of‑pipe solutions.

1.2 The opportunity

Smarter catchments use three complementary levers:

- Living systems (wetlands, reedbeds, green corridors, floodable parks) distributed across the network to intercept, store and treat.

- Biochemical augmentation (enzymes, microbial consortia) at key nodes to prevent blockages, reduce fats, oils and grease (FOG), and pre‑condition organics for downstream treatment.

- Data and control (sensors, telemetry, analytics, optimisation) to anticipate events, balance capacity across networks, and release or retain water at optimal times.

Individually, each lever has a track record. Combined, they deliver non‑linear gains: fewer spills, lower peak loads, better effluent quality, deferred capex, and an adaptable system that improves with data.

2. Core components of a smarter catchment

2.1 Living systems: wetland and reedbed infrastructure

Constructed wetlands and reedbeds provide low‑energy, high‑reliability treatment. Placed strategically, they reduce loads reaching sensitive water bodies and treatment works. Key typologies include:

- Surface flow wetlands: Shallow basins with emergent macrophytes, suited for polishing stormwater and attenuating flow.

- Subsurface horizontal flow reedbeds: Water flows through gravel media colonised by reeds (e.g., Phragmites), promoting aerobic/anaerobic microzones suitable for BOD and ammonia reduction.

- Vertical flow beds: Alternating dosing and rest cycles enhance oxygen transfer, boosting nitrification.

- Hybrid trains: Combinations designed to target specific pollutants (BOD, TSS, ammonia, nitrate, phosphate), often in series with forebays for sediment control.

Benefits:

- Passive resilience: Performance stabilises over time as microbial and plant communities mature.

- Multi‑benefits: Carbon sequestration, urban cooling, biodiversity habitat, amenity and education.

- Modular and scalable: Can be integrated into brownfield pockets, riparian zones, or retrofitted into parks and green corridors.

Design principles:

- Place near load sources for pre‑treatment and along conveyance routes for polishing.

- Provide bypasses and adjustable weirs for protectable hydraulic operation.

- Size for both water quality (hydraulic retention time) and quantity (storage for storm attenuation).

- Include sediment forebays and maintenance access to manage clogging risk.

- Use native plant species and design for year‑round function.

2.2 Enzymes and bioaugmentation: biochemical leverage

Enzyme dosing and targeted bioaugmentation offer a flexible way to reduce FOG, enhance hydrolysis of complex organics, and temper odour and septicity—especially at hotspots such as CSO chambers, wet wells, rising mains and downstream of food service clusters.

Mechanisms:

- Enzymes catalyse the breakdown of fats, proteins, carbohydrates and complex organics into simpler substrates that are more readily metabolised by indigenous microbes.

- Bioaugmentation introduces robust, non‑pathogenic microbial consortia adapted to sewer conditions to accelerate biodegradation and outcompete odour‑forming organisms.

- Septicity control reduces hydrogen sulphide (H2S) formation, protecting assets from corrosion and mitigating health and odour issues.

Operational notes:

- Dosing control: Start with site‑specific jar tests or pilot dosing to determine optimal enzyme blend and dose rates; couple with flow‑proportional dosing where feasible.

- Placement: Install dosing rigs at upstream network nodes, wet wells, or interceptors to pre‑condition wastewater and first flushes.

- Monitoring: Track surrogate measures (e.g., H2S, dissolved oxygen, temperature, pH, COD/BOD grabs) and operational indicators (blockage rates, FOG accumulation).

- Safety and compliance: Use products with established environmental and health safety profiles; maintain logs of dosing rates, volumes, and observed outcomes.

Results to expect:

- Lower FOG build‑up and fewer blockages; reduced jetting frequency.

- Improved pump efficiency and reduced power draw.

- Lower BOD/COD spikes at treatment works after storm events.

- Potential CSO quality improvements in terms of dispersed vs. emulsified organics.

2.3 Data and control: the nervous system

Smart catchments are made possible by an integrated digital layer comprising:

- Sensors: Level, flow, rainfall, turbidity, dissolved oxygen, conductivity, ammonium, nitrate, phosphate (selectively), temperature, H2S.

- Telemetry: Low‑power wide‑area networks (LPWAN), cellular, or fibre connections, with robust power strategies (mains, solar, battery packs).

- Edge control: Motorised penstocks, smart gates, variable speed pumps, and distributed logic for local fail‑safe operation.

- Analytics: Forecast‑informed control, event detection (first flush, illicit discharges), network optimisation, and data quality assurance.

- Dashboards: Real‑time situational awareness, performance KPIs, compliance tracking, and maintenance prompts.

- Digital twins: Steady‑state and dynamic models calibrated with live data to test strategies (e.g., pre‑emptive storage, dosing schedules, weir set‑points).

With these tools, operations move from reactive to anticipatory: proactively drawing down storage before storms; throttling flows to avoid downstream overload; dosing enzymes ahead of predicted FOG load surges; and routing water towards wetlands when capacity and treatment conditions are favourable.

3. System architecture: how the pieces fit

Think of a catchment as a federation of sub‑catchments, each with its own hydrology, sources of pollution, and constraints. The goal is to orchestrate flows and treatment along a series of nodes and pathways.

- Upstream capture and conditioning:

- Permeable surfaces, swales and rain gardens slow and filter runoff;

- Smart kerb inlets and storm interceptors capture gross solids;

- Enzyme dosing rigs treat FOG‑rich inflows from food clusters or combined sewers with known blockage histories.

- Mid‑stream attenuation and treatment:

- Constructed wetlands and reedbeds provide storage and water quality performance;

- Smart penstocks modulate retention time based on flow forecasts and real‑time quality sensors.

- Network capacity balancing:

- Interconnected detention assets (tanks, oversized pipes, floodable greens) become a “virtual reservoir”;

- Control logic redistributes flows to prevent localised surcharges and CSOs.

- Downstream polishing and discharge:

- Final reedbeds and filter systems near outfalls polish effluent;

- Live monitoring of surrogate parameters ensures compliance and enables adaptive management.

- Interface with treatment works:

- Pre‑conditioned inflows reduce shock loading and energy consumption;

- Data exchange aligns catchment operations with works capacity, especially under storm blending conditions.

4. Deployment roadmap

4.1 Phase 1: Baseline and opportunity mapping

- Data audit: Collate historic CSO events, rainfall records, blockage logs, CCTV surveys, pumping data, and water quality samples.

- Rapid network screening: Identify hotspots (frequent spills, FOG accumulation, odour complaints, low gradient reaches).

- Nature‑based siting: Map land opportunities (public parks, school grounds, riparian strips, brownfields) with ownership and planning constraints.

- Quick wins: Select 5–10 priority sites for immediate pilots—typically a mix of enzyme dosing at a problematic node, a reedbed retrofit, and a telemetry upgrade.

Deliverables: Baseline performance dashboard; site shortlist; pilot designs; stakeholder engagement plan.

4.2 Phase 2: Pilot and learning loops

- Instrumentation: Install level/flow sensors, rainfall gauges, and low‑maintenance water quality probes with data validation routines.

- Enzyme/bioaugmentation pilots: Deploy dosing rigs with remote rate control; compare before/after blockage frequency, FOG thickness, H2S trends and pump draw.

- Wetland/reedbed pilots: Build at least one modular system with adjustable hydraulics; track hydraulic retention time (HRT), inflow/outflow quality, and seasonal effects.

- Control trials: Fit motorised gates at a CSO chamber to dynamically control set‑points pre‑storm.

- Evaluation: Use a pre‑agreed benefit framework (CSO volume reduction, event frequency, pollutant load reduction, energy, OPEX savings) and run sensitivity analyses.

Deliverables: Pilot reports with robust statistics; refined design parameters; user training materials; community feedback.

4.3 Phase 3: Scale‑out and integration

- Portfolio design: Sequence wetlands, green corridors, and storage assets as a logical network; standardise dosing skids and telemetric units.

- Control architecture: Implement a hierarchical control scheme—local asset control with central optimisation that respects constraints and fails safe.

- Digital twin calibration: Blend hydrodynamic modelling with machine learning for short‑term forecasting of flows and quality; calibrate with pilot data.

- Procurement scaling: Create framework contracts for NBS construction, dosing consumables, and sensor maintenance with performance‑based clauses.

- Governance: Establish joint operations groups between utilities and councils with shared dashboards and response protocols.

Deliverables: Integrated investment case; construction programme; operating handbook; resilience and contingency plans.

4.4 Phase 4: Optimisation and continuous improvement

- Seasonal tuning: Adjust dosing and set‑points with temperature and antecedent dry weather periods.

- Asset rotation: Rest and refurbish NBS cells periodically to preserve treatment efficacy; schedule sediment removal based on triggers.

- Algorithm improvements: Incorporate new data to refine event prediction, anomaly detection and maintenance planning.

- Public communications: Publish accessible performance summaries and involve communities in stewardship of green assets.

Deliverables: Annual performance report; updated optimisation rules; community co‑management agreements.

5. Performance pathways: how the benefits accrue

5.1 CSO reduction

- Storage and attenuation: Wetlands, reedbeds and distributed detention assets reduce peak flows, smoothing hydrographs.

- Forecast‑informed drawdown: Smart control pre‑emptively lowers ponded levels ahead of rainfall, creating headroom.

- Source conditioning: Enzyme dosing reduces FOG‑induced constrictions and increases effective pipe capacity; fewer blockages mean fewer surcharge‑driven spills.

Expected outcomes: Lower event frequency and volume; shorter duration spills; improved compliance with permit thresholds; reduced “first flush” pollutant shock loads.

5.2 Nutrient and organics control

- Wetland processes:

- BOD/COD reduction via microbial decomposition and plant uptake;

- Ammonia oxidation in oxygenated zones (nitrification) followed by denitrification in anoxic niches;

- Phosphate capture by adsorption to media and plant uptake (with periodic biomass management).

- Enzyme/bioaugmentation pre‑conditioning: Converts complex organics into more biodegradable forms, reducing peak loads at works and within NBS, improving overall removal efficiencies.

- Monitoring‑led routing: Diverts water to the most effective treatment train based on current conditions, preventing overloading.

5.3 Asset health and operational efficiency

- Pumping stations experience fewer clogs, less ragging, and lower energy draw.

- Reduced corrosion from lower H2S prolongs asset life and decreases confined‑space interventions.

- Better flow balance across the network defers expensive upsizing of pipes and tanks.

5.4 Climate resilience and co‑benefits

- Distributed green infrastructure provides thermal moderation, pollinator habitat, and recreational space.

- Systems remain functional during power or comms outages thanks to passive NBS and fail‑safe controls.

- Green corridors and “blue‑green” retrofits help manage urban heat and support active travel networks.

6. Economics and lifecycle cost

6.1 Capital efficiency

- NBS costs are often lower than hard engineering for equivalent water quality outcomes and can utilise marginal land.

- Enzyme dosing systems have relatively low capex and can be rapidly installed at problematic nodes.

- Smart control transforms existing tanks and oversized pipes into actively managed storage, extracting value from sunk assets.

6.2 Operating costs

- Dosing OPEX is offset by fewer reactive callouts, reduced jetting, and energy savings at pumps and works.

- Wetlands require periodic vegetation management and sediment removal rather than intensive energy and chemical inputs.

- Predictive maintenance reduces emergency interventions and extends asset life.

6.3 Cost–benefit framing

- Consider avoided CSO penalties and reputational risks, deferred capex, carbon impact, biodiversity net gain, and health benefits.

- Express benefits as £/m³ CSO avoided, £/kg BOD or P removed, or £ per avoided blockage to enable fair comparison across interventions.

- Use scenario analysis to account for climate uplift and regulatory tightening.

7. Measurement, verification and KPIs

Define quantitative KPIs at programme inception and maintain transparency:

- CSO metrics: Number of events per outfall per season; spill volume; duration; first‑flush loads.

- Water quality: Influent/effluent BOD, COD, TSS, ammonia, nitrate, phosphate; surrogate measures (turbidity, conductivity, DO).

- Operations: Blockage frequency, jetting hours, pump energy use, odour complaints.

- NBS health: Vegetation coverage, media headloss, sediment accumulation, biodiversity indicators.

- Financials: OPEX vs baseline, avoided cost estimates, capex deferrals.

- Carbon: Embedded and operational emissions compared to conventional solutions.

Verification practices:

- Use paired “before/after” and control‑site comparisons.

- Employ data quality flags, drift checks and calibration routines for sensors.

- Conduct independent audits annually and publish accessible summaries.

8. Engineering and design guidance

8.1 Wetlands and reedbeds

- Hydraulics: Maintain uniform distribution of flows with inlet/outlet structures to prevent short‑circuiting; design for variable water levels with adjustable weirs.

- Media: Use graded aggregates for subsurface systems to balance permeability and biofilm support.

- Oxygen transfer: For vertical flow systems, adopt dosing/rest cycles; for horizontal beds, use intermittent aeration only if warranted by performance.

- Redundancy: Build multiple cells to allow rotation and maintenance without service interruption.

- Cold‑weather resilience: Increase HRT for winter; plant species selection for cold tolerance; include deeper refuge zones.

- Flood compatibility: Provide overtopping paths that avoid erosion and protect plant root systems.

8.2 Enzyme dosing systems

- Site selection: Target persistent FOG hotspots, septicity‑prone reaches, and nodes that influence key CSO outfalls.

- Dosing control: Flow‑proportional metering where possible; otherwise, risk‑based schedules informed by rainfall forecasts and diurnal patterns.

- Compatibility: Verify compatibility with downstream processes; avoid antagonism with essential biological stages at the treatment works.

- Safety and storage: Secondary containment for chemicals; labelling and spill kits; tamper‑evident housings.

8.3 Sensing and control

- Sensor placement: Combine upstream rainfall and downstream flow sensors to anticipate backwater effects; place quality sensors where maintenance access is feasible.

- Power: Solar/battery for remote sites; mains with UPS for critical nodes.

- Communications: Dual path (e.g., cellular plus LPWAN) for resilience at critical controls.

- Cybersecurity: Secure protocols, role‑based access, network segmentation, and audit trails.

- Failsafe logic: Default gates to safe positions on comms loss; local control rules to preserve basic functionality.

9. Governance, procurement and delivery

9.1 Partnership models

- Utility–council joint programmes with shared KPIs align incentives around CSO reduction and urban amenity.

- Catchment forums with environment agencies, NGOs, and community groups build trust and enable land access.

- Outcome‑based contracts reward verified load reductions and availability rather than unit rates or inputs.

9.2 Procurement essentials

- Frameworks for NBS design–build–maintain with performance bonds and adaptive management clauses.

- Dosing consumables via call‑off contracts with service‑level agreements on response time and telemetry support.

- Data platforms specified for interoperability (open APIs, standard data schemas) and long‑term maintainability.

9.3 Skills and training

- Cross‑disciplinary teams spanning civil/environmental engineering, ecology, data science, operations and community engagement.

- Training for field teams on sensors, dosing safety, NBS maintenance and basic data interpretation.

- Knowledge capture from pilots to standard operating procedures (SOPs) and playbooks.

10. Community, equity and communications

Smarter catchments work best when residents understand and value them.

- Co‑design green assets with local users to improve safety, accessibility and stewardship.

- Provide simple interpretive signage explaining how reedbeds and wetlands improve river health.

- Share live performance snapshots and celebrate milestones (e.g., CSO‑free months, biodiversity sightings).

- Ensure equitable distribution of benefits—prioritise interventions in communities disproportionately affected by flooding, odour and poor water quality.

11. Risk management and safeguards

- Performance variability: NBS and biological processes vary seasonally; counter with hybrid trains, adjustable hydraulics and proactive winter set‑point changes.

- Sensor reliability: Mitigate fouling and drift with cleaning schedules, redundancy and automated data quality checks.

- Dosing risks: Over‑ or under‑dosing; address with remote monitoring, lockable set‑points and alarms; always validate product selection and concentrations.

- Land and planning: Early engagement with planners and landowners; use modular designs and temporary planning routes when appropriate.

- Health and safety: Confined space protocols, odour management, and vector control around wetlands; design for safe access and egress.

- Governance drift: Maintain clear accountabilities with RACI matrices and routine joint operations reviews.

12. Regulatory alignment and reporting

- Align interventions with storm overflow reduction plans and river basin management objectives.

- Use quantified evidence of CSO event reductions, load removals and ecological improvements to demonstrate compliance and value.

- Maintain transparent public reporting on spill events and water quality, with contextual explanations and corrective actions.

13. Funding and financing options

- Capital programmes: Integrate smarter catchment portfolios into regulated price control submissions with robust cost–benefit narratives.

- Nature‑based and biodiversity funds: Leverage biodiversity net gain credits, urban greening funds, and partnerships with developers.

- Outcome‑based mechanisms: Consider pay‑for‑performance structures tied to verified reductions in CSO volumes or pollutant loads.

- Community co‑funding: Small grants and sponsorships for pocket wetlands, school reedbeds and monitoring kiosks.

14. A worked example: a typical urban sub‑catchment

Consider a 1,200‑hectare mixed‑use urban area with a combined sewer network, three CSO outfalls, two pumping stations and chronic FOG issues near a food precinct.

Intervention set:

- Install rainfall, level and flow sensors at critical nodes; add turbidity and conductivity at two outfalls.

- Retrofit motorised penstocks at a key CSO chamber and a downstream detention tank.

- Construct two modular reedbed cells (each 1,500 m²) alongside a riparian green corridor, with forebays and adjustable weirs.

- Deploy enzyme dosing at two upstream wet wells and one interceptor near the food precinct, with flow‑proportional control and telemetry.

- Reconfigure a riverside park as a floodable green storage area with subtle bunding and planting.

Operations:

- Before forecasted storms, lower detention levels and wetland water surfaces to maximise available storage.

- Initiate pre‑storm dosing to address anticipated first‑flush organics and FOG mobilisation.

- During events, throttle flows at the CSO chamber to prioritise routing into the detention tank and wetlands while monitoring quality thresholds.

- After events, maintain dosing briefly to speed system recovery; rotate reedbed cells to maintain treatment performance.

Outcomes (illustrative):

- 35–50% reduction in annual CSO volumes and 40% reduction in event frequency.

- 25–40% reduction in BOD loads at outfalls; measurable attenuation of ammonia and orthophosphate depending on HRT.

- 60% reduction in blockage incidents and 30% drop in jetting hours.

- Deferred capex for pipe upsizing and reduced energy draw at pumps, offsetting dosing OPEX.

15. Practical tips and pitfalls to avoid

- Start small, prove value, then scale. Pilots reduce risk and generate local champions.

- Don’t treat sensors as “fit and forget.” Budget time and materials for regular cleaning and calibration.

- Expect seasonality. Design for it and communicate it—performance gains over a year matter more than a single storm.

- Keep wetlands simple and maintainable. Over‑engineering can introduce failure modes and maintenance burdens.

- Integrate operations teams early; designs must reflect how assets will actually be run at 2am in a storm.

- Use open, interoperable data systems to avoid vendor lock‑in and enable continuous improvement.

- Track and publicise co‑benefits—amenity, biodiversity, reduced odour—because they matter to decision‑makers and the public.

16. The path ahead

The smartest catchments are not the most gadget‑laden; they are the ones that combine the quiet reliability of living systems with precisely targeted biochemical tools and the lightest touch of data‑informed control. This synthesis delivers immediate operational gains while building long‑term resilience and public value. For UK water companies and councils, it offers a credible roadmap to cut CSO loads and nutrient and organic pollution at a lower lifecycle cost—and to do so in a way that leaves towns and rivers greener, cooler and more vibrant.

The transition can begin today with a handful of pilots. Within a price control period, programmes can scale to cover whole districts. Within a decade, catchments can be re‑shaped to work with nature, supported by enzymes and guided by data—a future where fewer spills, cleaner rivers and thriving communities become the norm rather than the exception.

Frequently asked questions

- How do enzymes differ from adding chemicals like ferric or hypochlorite?

Enzymes are biological catalysts that accelerate the breakdown of specific compounds (e.g., fats, proteins, carbohydrates) into smaller, more biodegradable forms without being consumed in the reaction. They typically act under ambient conditions and are selected for target substrates. Ferric salts and other chemicals act via precipitation or oxidation and can increase sludge volumes or introduce secondary effects. Enzyme dosing is particularly useful for FOG control, odour/septicity mitigation and pre‑conditioning organics, and it can be used alongside conventional chemicals where necessary. - Will constructed wetlands work in winter and during prolonged wet periods?

Yes, but with adjusted expectations and design. Biological rates slow in cold conditions, so designs should allow longer hydraulic retention times and incorporate deeper refuge zones. Hybrid configurations (e.g., vertical flow plus horizontal subsurface) and adjustable hydraulics help sustain performance. Even during wet periods, wetlands deliver attenuation, solids capture and partial nutrient removal. Rotating cells, maintaining vegetation health and ensuring good inlet distribution are key to winter resilience. - How do we know the smarter catchment is working without adding a complex lab programme?

Use a layered monitoring approach. Combine robust surrogate sensors (level, flow, turbidity, conductivity, dissolved oxygen and H2S) with periodic grab samples for BOD, COD, ammonia, nitrate and phosphate. Automate data quality checks and maintain calibration routines. Track operational metrics (blockages, jetting hours, odour complaints) as leading indicators. Establish a clear baseline, then compare like‑for‑like periods (e.g., season to season) and use independent audits annually to verify performance. - What are the main maintenance burdens we should plan for?

- Sensors: Routine cleaning, calibration and battery/solar maintenance.

- Dosing rigs: Refill schedules, pump checks, hose replacement and telemetry health.

- Wetlands/reedbeds: Vegetation management (cutting/harvesting), litter removal, sediment forebay dredging, media headloss checks and periodic cell resting.

- Controls: Exercising valves and penstocks, verifying failsafe operation, and firmware updates.

With a planned regime, these activities are predictable and less costly than reactive maintenance on blockages and overflows.

- Will a smarter catchment approach lock us into specific vendors or proprietary platforms?

It does not have to. Specify open data standards, interoperable APIs, and modular components during procurement. Prioritise suppliers who support exportable data and configurable controls. Maintain internal capability to interpret data and adjust operations. The most resilient programmes combine vendor expertise with in‑house oversight and a commitment to transparency.

Appendix: indicative KPI set for programme governance

- CSO performance:

- Events per outfall per quarter

- Total annual spill volume

- First‑flush pollutant load reduction (BOD/TSS/PO4 surrogate indices)

- Water quality:

- Inflow/outflow BOD, COD, TSS, NH4‑N, NO3‑N, PO4‑P at representative assets

- Turbidity, DO, conductivity, temperature, H2S at critical nodes

- Operational efficiency:

- Blockages per 10 km of sewer

- Jetting hours per month

- Pump kWh per megalitre pumped

- NBS asset health:

- Vegetation cover and vigour indices

- Sediment depth in forebays

- Media headloss indicators

- Financial and carbon:

- OPEX vs baseline and avoided reactive costs

- Capex deferral quantified

- Operational carbon intensity (kg CO2e/ML managed)

- Community:

- Odour complaints

- Public satisfaction and engagement metrics

- Biodiversity observations (e.g., indicator species presence)

This blueprint provides the practical pathway for utilities and councils to move beyond piecemeal upgrades and towards integrated catchments that blend the best of ecology, biochemistry and digital intelligence. By focusing on measurable outcomes—fewer CSOs, lower nutrient and organic loads, improved resilience, and better value for money—smarter catchments can transform river health and urban liveability across the UK.

Bioglobe offer Organic Enzyme pollution remediation for major oil-spills, oceans and coastal waters, marinas and inland water, sewage and nitrate remediation and agriculture and brown-field sites, throughout the UK and Europe.

We have created our own Enzyme based bioremediation in our own laboratory in Cyprus and we are able to create bespoke variants for maximum efficacy.

Our team are able to identify the pollution, we then assess the problem, conduct site tests and send samples to our lab where we can create a bespoke variant, we then conduct a pilot test and proceed from there.

Our Enzyme solutions are available around the world, remediation pollution organically without any harm to the ecosystem.

For further information:

BioGlobe LTD (UK),

Phone: +44(0) 116 4736303| Email: info@bioglobe.co.uk