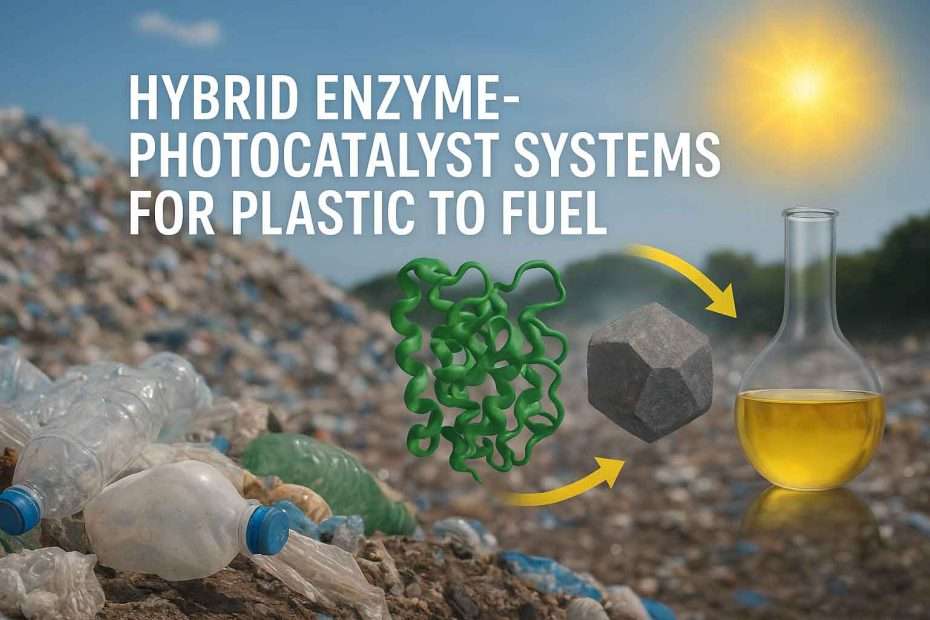

Hybrid Enzyme-Photocatalyst Systems for Plastic to Fuel

Introduction

The global crisis of plastic pollution has escalated into one of the most pressing environmental challenges of the 21st century. Every year, millions of tonnes of plastic are produced, consumed, and discarded, much of it ending up in landfills, rivers, and oceans. Despite the vast scale of this issue, progress on sustainable and effective solutions has been slow. Conventional recycling methods are limited by economics, technology, and infrastructure, while incineration and landfilling simply shift the problem elsewhere, creating greenhouse gases, toxins, and persistent microplastics.

Against this background, scientists and innovators have been searching for solutions that can not only break plastics down but also upcycle them into useful materials, ideally under mild and environmentally friendly conditions. Two approaches stand out as particularly promising: enzymatic degradation, which uses biological catalysts to break polymers into smaller molecules, and photocatalytic reforming, which uses light and catalysts to convert plastics into fuels and valuable chemicals.

Both methods have strengths and weaknesses. Enzymes offer high specificity, operate under relatively mild conditions, and are biodegradable, but they can struggle with the most chemically resistant plastics. Photocatalysts, by contrast, can break even the most recalcitrant bonds using solar or artificial light, but they often require harsh conditions and can lack selectivity.

The exciting development lies in combining these two approaches into hybrid enzyme-photocatalyst systems. This forward-looking strategy offers a pathway to transform plastic waste into usable fuels, such as hydrogen or ethanol, with minimal adverse impact on ecosystems.

Bioglobe, with its expertise in organic enzyme remediation, is well positioned to contribute to this frontier. From its laboratories in Cyprus and operations in the United Kingdom, Bioglobe develops bespoke enzyme formulations tailored to specific pollutants. This capability, combined with a commitment to organic, safe, and ecosystem-friendly methods, makes Bioglobe an ideal contributor to the development of hybrid solutions that turn plastic waste into fuel without harming the environment.

The Problem: Plastic Waste and Its Intractability

Plastic has become indispensable in modern society. Its durability, versatility, and low cost have led to its use in packaging, construction, textiles, electronics, and countless other applications. Yet these very qualities make plastic a formidable pollutant. Unlike organic matter, plastic does not readily degrade. A plastic bottle can persist in the environment for centuries, slowly breaking down into microplastics but not fully disappearing.

The sheer volume of plastic waste is staggering. Global production exceeds 400 million tonnes per year, and only a small fraction of this is effectively recycled. Much of it ends up either incinerated, releasing carbon dioxide and toxic gases, or discarded in landfills and natural environments. Rivers carry plastic waste to oceans, where it accumulates in gyres and coastal zones, creating massive patches of floating debris and infiltrating marine ecosystems.

Microplastics, formed from the breakdown of larger pieces or released directly from products such as synthetic textiles, have become an invisible but ubiquitous contaminant. They are found in soil, water, air, and even human bloodstreams. They act as carriers for other pollutants, absorb heavy metals and toxins, and threaten ecosystems at every level.

The resilience of plastics lies in their chemical structures. Polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are examples of polymers with strong carbon-carbon backbones and complex additives that resist both biological and chemical attack. Traditional recycling methods cannot cope with the diversity and contamination of real plastic waste streams, while incineration sacrifices the embedded carbon and energy value of plastics in return for new environmental burdens.

This situation leaves the world in urgent need of methods that can address plastic pollution in ways that are both effective and sustainable.

Consequences of Inaction

If the world fails to address plastic pollution, the consequences will continue to multiply.

Environmental Consequences: Plastics persist in ecosystems, entangling wildlife, blocking waterways, and releasing additives such as phthalates and bisphenol A, which disrupt biological processes. Microplastics are ingested by fish, birds, and mammals, accumulating in food chains and potentially reaching humans.

Climate Consequences: Incinerating plastic releases greenhouse gases, contributing to climate change. Landfilled plastics may release methane as they degrade anaerobically, compounding the climate burden.

Economic Consequences: The cost of collecting, transporting, and disposing of plastic waste is enormous, and the damage to fisheries, tourism, and agriculture from polluted environments imposes further financial losses. At the same time, the embedded carbon and energy value of plastics is wasted rather than recovered.

Social and Regulatory Consequences: Governments around the world are tightening regulations on single-use plastics and imposing stricter waste management requirements. Companies that fail to adopt sustainable solutions face reputational and financial risks. Communities, meanwhile, suffer directly from polluted rivers, contaminated soils, and declining biodiversity.

The failure to act is not simply an environmental issue but a global economic and social challenge.

The Solution: Hybrid Enzyme-Photocatalyst Systems

The Concept

Hybrid enzyme-photocatalyst systems represent an innovative approach to tackling plastic pollution while generating value. These systems combine the specificity and mild operating conditions of enzymes with the energy and power of photocatalysis.

Enzymes can act as the first line of attack, binding to polymer surfaces and catalysing the breakdown of susceptible bonds. For example, PETase, an enzyme discovered in bacteria at a recycling plant, can degrade polyethylene terephthalate into its monomers. Other enzymes can oxidise or hydrolyse different polymers, reducing their resistance to further breakdown.

Photocatalysts, often based on semiconductors such as titanium dioxide (TiO₂) or graphitic carbon nitride (g-C₃N₄), use light energy to excite electrons, creating reactive oxygen species that attack chemical bonds. When combined with enzymes, photocatalysts can take over where biological activity slows, fragmenting resistant structures or converting degradation products into smaller fuels and chemicals.

The synergy lies in the fact that enzymes and photocatalysts target different aspects of the problem. Enzymes weaken and fragment plastics under benign conditions, while photocatalysts convert these fragments into fuels such as hydrogen or ethanol using solar energy.

Recent Advances

Recent scientific progress has demonstrated that such systems are viable. Photocatalysts have been shown to reform plastics into ethanol under neutral aqueous conditions, avoiding the need for harsh pre-treatment. Enzyme-photocatalyst hybrids have been tested for their ability to break down polyester plastics more efficiently than either method alone. Floating, hybrid catalysts that can remain stable on water surfaces and operate under sunlight have achieved higher yields than traditional photocatalysts.

These advances suggest that hybrid systems could soon move from laboratory proofs of concept to pilot-scale applications.

How Hybrid Systems Work

Step 1: Characterisation of Plastic Waste

The first step is to understand the composition of the plastic waste. Different plastics respond to different treatments. Polyesters like PET are susceptible to hydrolytic enzymes, while polyethylene and polypropylene may require oxidation or radical-based pathways. Bioglobe’s laboratory capabilities allow precise identification of pollutants, ensuring that the correct enzyme formulations are developed for each situation.

Step 2: Enzymatic Pre-Treatment

Enzymes are applied to weaken or partially degrade the plastic surface. This step improves hydrophilicity, exposes reactive sites, and produces fragments that are more accessible to photocatalytic processes. Unlike harsh chemical pre-treatments, enzymatic methods operate under mild pH and temperature conditions and do not release toxic by-products.

Step 3: Photocatalytic Reforming

Once the plastic has been softened or fragmented by enzymes, photocatalysts use light energy to further break bonds and convert the material into fuels. Under sunlight or artificial illumination, catalysts such as TiO₂ can generate radicals that cut polymer chains, releasing small hydrocarbons, alcohols, or hydrogen gas.

Step 4: Synergy Between Enzymes and Photocatalysts

In some cases, enzymes can be immobilised on or near photocatalyst surfaces, creating true hybrids. This arrangement allows enzymes to act on intermediates created by photocatalysis, preventing over-oxidation, and enhances overall selectivity for valuable products.

Step 5: Recovery and Reuse

For any practical system, catalysts and enzymes must be recoverable and reusable. Hybrid systems can be designed with immobilised or floating supports, ensuring that nothing harmful is released into the environment.

Bioglobe’s Role in Developing Hybrid Systems

Bioglobe’s expertise in organic enzyme remediation provides a critical contribution to the development of hybrid enzyme-photocatalyst systems.

Bespoke Enzyme Formulations

Because different plastics require different enzymatic strategies, the ability to design and produce bespoke enzyme blends is invaluable. Bioglobe’s laboratory in Cyprus analyses pollutants and tailors enzyme variants to maximise efficacy in each case.

Ecosystem Safety

Bioglobe’s solutions are organic and biodegradable, designed to leave no harmful residues in the environment. This commitment ensures that hybrid systems using Bioglobe enzymes operate without adverse effects on ecosystems.

Integration with Photocatalysts

While Bioglobe specialises in enzymes, collaboration with photocatalyst researchers and engineers allows for the development of integrated systems. Bioglobe’s enzymes can act as the biological component, pre-treating plastics or operating in tandem with light-driven catalysts to achieve complete conversion.

Real-World Application

Unlike many laboratory-based concepts, Bioglobe’s work is grounded in real environmental challenges: oil spills, sewage contamination, algae blooms, and plastic pollution in waterways. This practical experience positions Bioglobe to pilot hybrid systems in real-world scenarios, such as treating microplastics in rivers or upcycling plastic waste collected from coastal areas.

Challenges and Opportunities

Challenges

- Enzyme Stability: Enzymes can be sensitive to heat, light, and reactive oxygen species. Protecting them in hybrid systems is essential.

- Photocatalyst Safety: Some catalysts rely on heavy metals or toxic components. Safer, more sustainable catalysts must be prioritised.

- Scalability: Laboratory success does not always translate to industrial scale. Reactors must be designed to ensure efficient light penetration and mixing.

- Economic Viability: Costs of enzyme production and catalyst materials must be reduced for widespread adoption.

Opportunities

- Solar Energy Integration: Hybrid systems powered by sunlight can operate with minimal external energy input.

- Microplastic Remediation: Enzyme-photocatalyst systems could target microplastics in water directly, a growing global concern.

- Circular Economy: Converting waste plastic into fuels and chemical feedstocks supports a circular economy, reducing reliance on virgin fossil resources.

- Regulatory Alignment: As governments demand greener solutions, companies using safe, organic methods like Bioglobe’s will be well placed to meet new standards.

Forward-Looking Potential

The combination of enzymes and photocatalysts is still a young field, but progress is accelerating. In the coming decade, it is likely that pilot systems will be deployed to test real-world applications. With further advances in enzyme engineering, photocatalyst design, and hybrid integration, large-scale systems that convert plastic waste into usable fuel under environmentally benign conditions may become a reality.

Bioglobe’s focus on organic, safe, and bespoke enzyme solutions ensures that the company will play an important role in this future. By partnering with researchers and industry, Bioglobe can help pioneer systems that not only address plastic pollution but also generate valuable resources, creating a win-win for the environment and the economy.

Conclusion

Plastic pollution is one of the defining environmental challenges of our time. Conventional methods of disposal and recycling have proved inadequate, leaving the world searching for solutions that are both effective and sustainable. Hybrid enzyme-photocatalyst systems represent a powerful new approach, combining the strengths of biology and photochemistry to convert plastic waste into fuels and valuable chemicals.

Bioglobe’s expertise in organic enzyme remediation positions it at the forefront of this development. By creating bespoke enzyme formulations, ensuring ecosystem safety, and applying real-world experience, Bioglobe can contribute to hybrid systems that are practical, scalable, and environmentally benign.

The vision is clear: plastic waste transformed into a resource, ecosystems protected, and the world one step closer to a circular economy. With innovation, collaboration, and commitment, hybrid enzyme-photocatalyst systems can help achieve this future — and Bioglobe is ready to lead the way.

Bioglobe offer Organic Enzyme pollution remediation for major oil-spills, oceans and coastal waters, marinas and inland water, sewage and nitrate remediation and agriculture and brown-field sites, throughout the UK and Europe.

We have created our own Enzyme based bioremediation in our own laboratory in Cyprus and we are able to create bespoke variants for maximum efficacy.

Our team are able to identify the pollution, we then assess the problem, conduct site tests and send samples to our lab where we can create a bespoke variant, we then conduct a pilot test and proceed from there.

Our Enzyme solutions are available around the world, remediation pollution organically without any harm to the ecosystem.

For further information:

BioGlobe LTD (UK),

Phone: +44(0) 116 4736303| Email: info@bioglobe.co.uk