Remediating the Sewers of London with Enzymes

Introduction

London is one of the great cities of the world, a thriving metropolis that combines history, culture, and innovation. Beneath its bustling streets, however, lies an extensive network of Victorian sewers that are increasingly struggling to cope with the demands of twenty-first century life. Designed in the mid-nineteenth century to serve a far smaller population and a simpler waste stream, this infrastructure now faces daily challenges from the by-products of modern living. Among the most pressing of these challenges are the blockages caused by fats, oils, and grease (commonly known as FOG), and the improper disposal of items such as wet wipes and sanitary products.

These issues are not just inconvenient. They carry significant financial costs, environmental risks, and public health implications. For Londoners, the spectacle of giant fatbergs being removed from sewer tunnels has become a grimly familiar news story. The city’s water utility spends millions of pounds every year on clearing these obstructions, yet the problem continues to recur.

There is, however, a sustainable and effective solution available. BioGlobe has pioneered the development of bespoke organic enzyme formulations that can break down the very substances responsible for blockages, while doing so in a way that is harmless to the environment. By applying such solutions to the London sewer system, the city can prevent fatberg formation, reduce maintenance costs, and safeguard both infrastructure and ecosystem health.

This article will explore the background of London’s sewage problems, examine the immediate issues in detail, and present the case for BioGlobe’s enzyme technology as a powerful, eco-friendly means of remediation.

Background

The Victorian Sewer System

London’s sewer network is a triumph of nineteenth-century engineering. Designed by Sir Joseph Bazalgette in the wake of the “Great Stink” of 1858, the system was revolutionary in its time. With more than a thousand miles of underground brick-lined tunnels, it transformed the health of the capital by diverting waste away from the Thames and reducing the risk of cholera outbreaks.

Yet Bazalgette himself understood that his design would one day be tested by the city’s growth. He deliberately built the tunnels to a larger capacity than was strictly necessary for the mid-Victorian era, anticipating an increase in population. But even his foresight could not have predicted the scale of London’s expansion over the next century and a half. Today, Greater London has nearly nine million residents, plus millions more commuters and visitors who pass through each day.

Modern Waste Streams

The waste entering the sewers of modern London is radically different from that of 1858. In the Victorian period, there were no cooking oils in vast quantities, no disposable wipes, no synthetic textiles, and no chemical detergents as we know them today. The waste was primarily organic matter and human sewage.

In contrast, the twenty-first century sewer system must cope with everything from fast food grease to cosmetic wipes, nappies, sanitary products, and even plastics. The combination of FOG with synthetic fibres has created entirely new challenges that the system was never designed to handle.

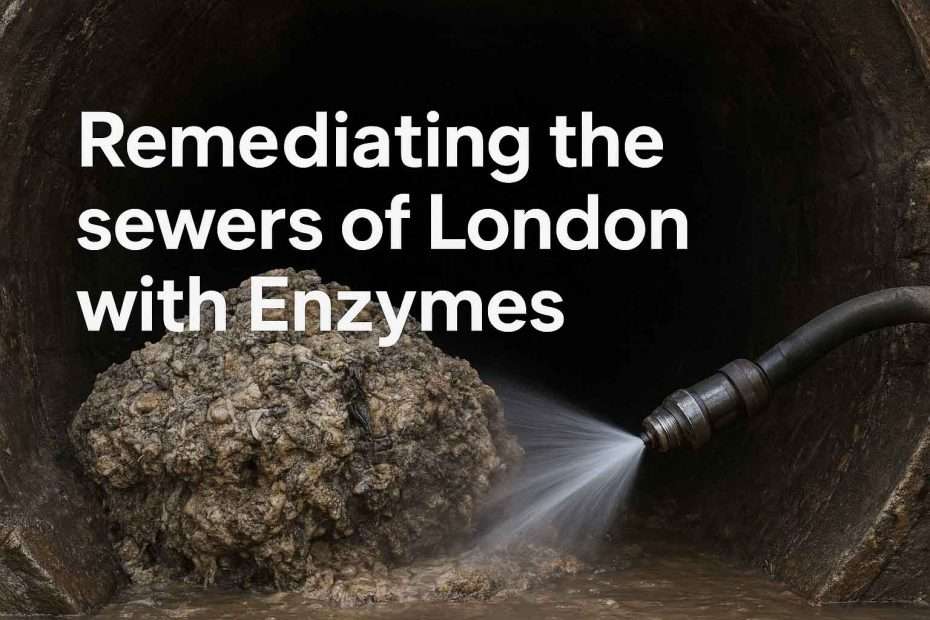

The Rise of the Fatberg

The word “fatberg” has entered the popular vocabulary to describe massive, solid blockages formed when fats, oils, and grease congeal in sewers and bind together with wipes, rags, and other debris. Some of these fatbergs weigh tens of tonnes and extend for hundreds of metres. Removing them requires teams of workers equipped with shovels, high-pressure water jets, and sometimes even heavy machinery.

Not only are fatbergs unsightly and hazardous, but they also cause significant disruption. They can reduce sewer capacity, leading to sewage backing up into streets and homes, and contribute to overflows that discharge untreated waste into rivers. Their removal consumes time, money, and energy, all of which could be saved if the underlying causes were addressed.

The Immediate Problems

Fat, Oil, and Grease (FOG) Accumulation

When households and restaurants pour cooking oil or grease down the sink, it may appear to flow away easily with hot water. But once it cools in the sewer pipes, it solidifies. These deposits cling to the walls of the sewer, creating a sticky base that traps other materials. Over time, the accumulation narrows the passage through which wastewater flows, eventually forming a complete blockage.

Restaurants, takeaways, and catering businesses are major contributors to FOG pollution. While grease traps and proper disposal methods exist, compliance is inconsistent, and in many cases, businesses lack the infrastructure or knowledge to manage fats properly.

Wet Wipes and Non-Biodegradable Waste

The second major factor in London’s sewer blockages is the widespread flushing of wet wipes, sanitary items, cotton buds, and other so-called “flushables.” Despite packaging claims, most wipes are not biodegradable in water. They remain intact long enough to bind with grease, creating a fibrous, rope-like structure within fatbergs.

A large proportion of blockages are caused by wipes, which constitute the backbone of fatbergs. The durability of synthetic fibres such as polyester and polypropylene means they persist in the sewer environment, resisting breakdown and adding to the volume of waste.

Blockages and Fatbergs

The combined effect of grease and wipes is the creation of hard, rock-like fatbergs. These structures can be metres thick, and in some cases, they are so solid that workers must physically chip them away with pickaxes. Once formed, fatbergs are extremely difficult to remove, and they can cause immediate disruption by blocking sewer flow.

Thames Water has reported spending tens of millions of pounds annually on clearing blockages. Each major fatberg incident becomes a costly operation requiring manpower, equipment, and time.

Ageing Infrastructure

Compounding the problem is the age of the sewer system itself. Much of Bazalgette’s original network is still in use, and while it was built to last, more than 150 years of constant use have taken their toll. Cracks, leaks, and structural weaknesses reduce efficiency and increase vulnerability to blockages.

The cost of upgrading or replacing London’s sewer system is astronomical, making it all the more important to find affordable ways to mitigate the immediate causes of blockages.

Costs of Maintenance and Repair

The direct costs of clearing blockages are immense, but there are also indirect costs. Blockages can lead to localised flooding, damage to property, and public health hazards. Businesses and households disrupted by sewage backups may suffer financial losses, and the environmental clean-up from sewer overflows adds to the burden.

Environmental and Health Impacts

When sewers overflow due to blockages, untreated sewage may enter rivers, contaminating watercourses and harming aquatic life. Pollutants such as microplastics from wipes and oils can disrupt ecosystems. For residents, exposure to raw sewage carries health risks, including gastrointestinal illness and infections.

These problems collectively highlight the urgent need for a solution that addresses the causes of fatbergs at source, rather than relying solely on costly removal after the fact.

The Solution: Organic Enzyme Remediation

What Enzymes Are and How They Work

Enzymes are natural biological catalysts that accelerate chemical reactions. In the context of wastewater treatment, enzymes can break down complex organic molecules into simpler, harmless components. Unlike harsh chemical treatments, enzymes are highly specific, targeting particular substances without damaging the surrounding environment.

For the problem of fatbergs, the most relevant enzymes are those capable of breaking down fats, oils, and organic fibres. By converting grease into smaller, water-soluble molecules, enzymes prevent it from solidifying in pipes. Similarly, enzymes that act on cellulose and other natural fibres can weaken the structure of wipes and tissues, reducing their ability to form blockages.

Why Enzymes Are Effective Against FOG

Traditional methods of dealing with FOG involve mechanical removal or the use of caustic chemicals. These approaches are labour-intensive, potentially harmful, and provide only temporary relief. Enzymes, on the other hand, address the problem at its root by changing the chemical structure of the offending materials.

Lipase enzymes break down fats into fatty acids and glycerol, both of which are soluble in water and can be flushed harmlessly through the sewer system. This prevents the initial adhesion of grease to sewer walls and reduces the risk of accumulation.

Tailoring a Bespoke BioGlobe Enzyme Solution

BioGlobe has extensive experience in developing enzyme formulations for environmental remediation, from oil spills to raw sewage treatment. This expertise allows us to design a bespoke enzyme blend specifically for the London sewer system.

The bespoke variant would combine several enzyme classes:

- Lipases and esterases to target fats, oils, and grease.

- Proteases to break down proteins present in food waste, which often bind with grease.

- Cellulases and hemicellulases to weaken the natural fibre components of wipes and tissues.

- Biofilm-degrading enzymes to disrupt the microbial matrices that hold debris together.

This carefully balanced formulation would be optimised for the pH, temperature, and oxygen levels found in London’s sewers, ensuring maximum effectiveness under real-world conditions.

Application Methods

The enzyme solution can be delivered in several forms:

- Liquid dosing directly into problem areas of the sewer network, using access points or dosing pumps.

- Encapsulated slow-release formulations that remain active over long periods, ensuring continuous prevention.

- Point-of-source dosing in commercial kitchens and food service establishments, treating fats before they enter the sewer system.

By combining preventive and remedial approaches, the enzyme solution would significantly reduce both the formation of new fatbergs and the growth of existing deposits.

Integration with Existing Practices

Enzyme remediation is not intended to replace mechanical maintenance entirely but to complement it. By reducing the volume and hardness of blockages, enzyme treatment makes routine cleaning easier, less costly, and less frequent. This integrated approach maximises efficiency and delivers long-term benefits.

Benefits to the Sewage System

Reduction in Fatberg Formation

The most direct benefit of enzyme treatment is the prevention of fatbergs. By breaking down fats and weakening wipe fibres, enzymes eliminate the key building blocks of blockages. This reduces the risk of catastrophic sewer blockages and ensures a smoother flow of wastewater.

Lower Maintenance Costs

With fewer blockages to clear, Thames Water and other stakeholders would save millions of pounds annually in labour, equipment, and emergency response costs. These savings could be redirected towards other infrastructure improvements.

Improved Sewage Flow and Capacity

A cleaner, obstruction-free sewer system can operate at its full designed capacity. This reduces the risk of localised flooding, improves resilience during heavy rainfall, and enhances the overall efficiency of wastewater management.

Enhanced Resilience of an Ageing System

Given the age of London’s sewers, preventing blockages is crucial to prolonging their lifespan. Enzyme treatment reduces the stress placed on pipes, minimises the risk of damage, and delays the need for costly replacements.

Complementary to Mechanical Cleaning

Mechanical cleaning, such as high-pressure jetting, can be disruptive and energy-intensive. By softening blockages in advance, enzyme treatment makes these interventions easier and less damaging to infrastructure. The result is a more balanced, sustainable maintenance regime.

Environmental Safety and Ecosystem Benefits

Biodegradability and Non-Toxicity

One of the greatest advantages of BioGlobe’s enzyme solutions is their environmental safety. Enzymes are biodegradable proteins that naturally break down over time. They do not persist in the environment or introduce harmful chemicals into watercourses.

No Harmful By-Products

Unlike harsh cleaning chemicals, enzyme treatment produces no toxic by-products. The breakdown of fats, oils, and organic matter results in harmless molecules such as fatty acids and sugars, which are further treated at wastewater plants or naturally assimilated.

Supporting Biodiversity

By reducing sewer overflows and preventing untreated waste from entering rivers, enzyme treatment helps protect aquatic life and maintain healthy ecosystems. Fewer blockages mean fewer incidents of pollution, safeguarding biodiversity in the Thames and its tributaries.

Circular Economy Considerations

The application of enzyme technology represents a shift towards sustainable, circular solutions in urban infrastructure. By working with natural processes rather than against them, enzyme remediation aligns with broader environmental goals such as reducing carbon footprints and promoting green innovation.

The Wider Vision

Preventive vs Reactive Management

At present, much of London’s sewer maintenance is reactive, responding to blockages after they occur. Enzyme remediation allows for a preventive approach, addressing problems at source and reducing the frequency of emergencies. This change in mindset is essential for building resilient urban systems.

Collaboration with Stakeholders

For maximum impact, enzyme solutions should be deployed in partnership with Thames Water, local councils, businesses, and residents. Point-of-source treatments in commercial kitchens can prevent large volumes of FOG from ever reaching the sewers, while regular dosing in hotspots can keep the network clear.

Public Education and Behavioural Change

While enzymes provide a powerful tool, behavioural change remains vital. Public campaigns to discourage flushing wipes and to promote responsible disposal of fats must accompany technical solutions. BioGlobe’s role can extend beyond supplying products to supporting awareness initiatives that empower communities.

Scaling Internationally

The problems facing London are not unique. Cities around the world are struggling with fatbergs and sewer blockages. Success in London could serve as a model for international deployment, allowing BioGlobe’s bespoke enzyme technology to benefit urban centres globally.

Conclusion

London’s sewers are a hidden marvel of engineering, but they are increasingly under threat from the challenges of modern waste. Fatbergs, blockages, and ageing infrastructure create a cycle of costly maintenance and environmental risk. Yet this is not an inevitable reality.

BioGlobe’s bespoke organic enzyme solutions offer a sustainable, effective, and eco-friendly means of remediation. By breaking down fats, weakening wipe fibres, and preventing blockages at source, enzymes can transform the way London manages its wastewater.

The benefits are clear: fewer fatbergs, lower costs, greater resilience, and a cleaner environment. Importantly, enzyme treatments are safe, biodegradable, and harmonious with natural ecosystems.

By adopting enzyme remediation, London has the opportunity to lead the way in sustainable sewage management. With BioGlobe’s innovation and expertise, the city can protect its infrastructure, safeguard its environment, and set a global example for how urban centres can thrive without being undermined by their own waste.

Bioglobe offer Enzyme pollution remediation for major oil-spills, oceans and coastal waters, marinas and inland water, sewage and nitrate remediation and also agriculture and brown-field sites, globally.

For further information:

BioGlobe LTD (UK),

Phone: +44(0) 116 4736303| Email: info@bioglobe.co.uk