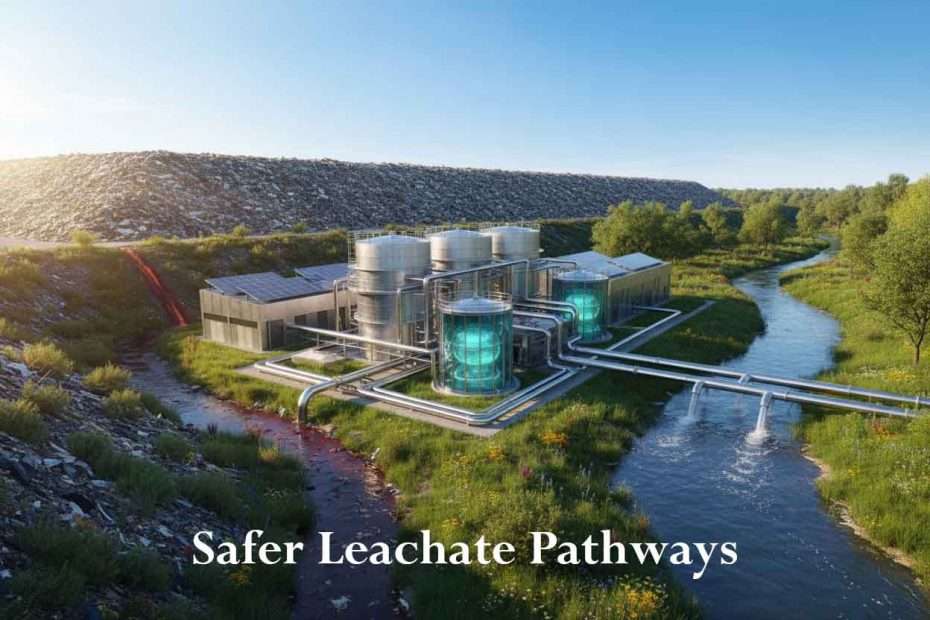

Safer Leachate Pathways

Treating landfill liquids before they reach the sewer

Introduction

Across the United Kingdom, beneath the surfaces of old landfills and waste disposal sites, a silent problem trickles away each day. Rainfall percolates through decades of decomposing waste, dissolving and carrying with it a complex mixture of contaminants known as leachate. This dark liquid is often rich in ammonia, organic residues, solvents, microplastics, and—most significantly—PFAS, the so‑called “forever chemicals.” For many years, the standard practice has been to send millions of tonnes of leachate to municipal wastewater treatment plants (WWTPs), where it is mixed with domestic sewage for biological treatment.

While this approach might seem logical on paper—after all, wastewater plants already handle polluted liquid—it has created an ecological and chemical feedback loop. Wastewater facilities were designed to treat human and animal waste, not the persistent, industrial pollutants found in landfill leachate. Their microbial and chemical treatment stages cannot effectively remove PFAS, flame retardants, or hydrocarbons, and in some cases, the processes within the plants can actually increase the concentration of PFAS compounds through biological transformation of precursor chemicals.

As a result, a large portion of these pollutants recirculates into the environment via treated water discharges and in sewage sludge used as agricultural fertiliser. The pollutants return to our rivers, farmland and food supply chain—undoing decades of environmental progress. This situation has raised growing concern among scientists, regulatory agencies, and communities living near both landfills and sewage works.

But there is a practical and sustainable alternative. Bioglobe, a pioneering biotechnology company based in Cyprus with operations in the UK, has developed an entirely organic enzyme remediation approach that can treat leachate safely before it enters the sewer network. This solution blends the precision of modern chemistry with the principles of ecological harmony. By using bespoke enzyme formulations—created specifically for the chemical composition of each leachate source—Bioglobe is enabling local authorities, landfill operators, and water companies to build a safer pathway for dealing with one of the country’s most stubborn environmental challenges.

Understanding the Leachate Problem

Landfill leachate forms when rain or groundwater passes through layers of waste material. It is not a uniform liquid; every landfill produces a unique chemical profile depending on the age of the waste, its composition, temperature, oxygen levels, and local geology. In general, freshly active landfill sites generate leachate rich in biodegradable organic matter, ammonia, and volatile fatty acids. Older sites create leachate dominated by persistent and less degradable chemicals.

Within the mix are traces of detergents, solvents, heavy metals, hydrocarbons, pharmaceuticals, and modern synthetic molecules like PFAS (per‑ and polyfluoroalkyl substances). These fluorinated chemicals, prized for their resistance to water and grease, have been used in consumer goods for decades—everything from non‑stick cookware to waterproof jackets and firefighting foam. Unfortunately, the same chemical bonds that make them useful also make them practically indestructible in the environment.

Historically, landfill leachate was collected in lagoons or sent for basic biological treatment before discharge to a sewer under permit. That practice continues today at hundreds of UK sites. According to independent investigations, more than three‑quarters of a million tonnes of landfill leachate enter sewage treatment networks each year. Once there, the concentrated chemical mixture combines with human sewage and industrial wastewater.

The biological systems in treatment plants struggle to process this influx. The leachate can inhibit microbial activity, reduce oxygen levels, and disturb nutrient removal processes. PFAS and other persistent substances slip through completely, surviving every stage of treatment to reappear in the liquid effluent discharged to rivers—or trapped within the sludge that is sold to farmers as fertiliser.

When PFAS‑containing sludge is spread on fields, the loop closes: rain and runoff return those substances to streams and groundwater, where they accumulate over time. What was once buried waste becomes a circulating pollutant—moving invisibly through soil, water, crops, and food.

The Consequences

The environmental and health consequences of unmanaged or poorly treated leachate are wide‑ranging:

1. Persistent chemical pollution.

PFAS compounds, known for their extraordinary chemical stability, have been detected in British surface waters and groundwater far beyond safe thresholds. They are resistant to sunlight, microbial decay, and heat, meaning they persist for decades. Once released, they are extremely difficult to remove.

2. Impaired wastewater treatment performance.

When large volumes of leachate are introduced into sewage systems, the balance of microbial life essential for biological treatment is disrupted. Ammonia and chemical oxygen demand (COD) levels increase, creating operational instability and higher energy costs.

3. Bioaccumulation in the food chain.

Many chemical compounds from leachate accumulate within living organisms. Fish exposed to contaminated water absorb PFAS, which are then consumed by humans. Crops grown on sludge‑treated farmland may contain measurable residues.

4. Deterioration of river and coastal ecosystems.

Even low concentrations of toxic compounds can affect aquatic species, damaging reproductive and immune functions and altering the balance of ecosystems.

5. Public trust and compliance costs.

Local councils, water companies, and landfill operators face rising pressure from regulators and the public to safeguard water quality. The cost of advanced chemical treatment systems continues to rise, while the pollution problem remains stubbornly unresolved.

Despite extensive regulation, current technology and practice continue to release pollutants into the environment. A new approach—one rooted in green chemistry and ecosystem safety—is required to break the cycle.

Bioglobe’s Organic Enzyme Solution

Bioglobe’s answer to this challenge is founded on a simple yet scientifically advanced principle: using nature’s own tools—enzymes and organic compounds—to speed up the natural breakdown and neutralisation of pollutants.

Enzymes are biological catalysts. They accelerate chemical reactions without being consumed themselves, acting with precise selectivity on target molecules. In Bioglobe’s laboratory in Cyprus, scientists have developed families of enzymes capable of attacking complex organic contaminants at a molecular level, transforming harmful compounds into benign by‑products such as carbon dioxide, nitrogen, and simple organic acids that the environment can safely assimilate.

Unlike conventional chemical treatments, Bioglobe’s enzyme blends are 100 per cent organic and plant‑derived. They are non‑toxic, non‑corrosive, and biodegradable. They leave behind no harmful residues, do not accumulate in the food chain, and do not disrupt aquatic ecosystems. In fact, the enzymes themselves eventually degrade into amino acids—essential building blocks of life.

Each formulation can be tailored precisely to the composition of the waste or pollution being treated. That flexibility is crucial because every landfill leachate has its own chemical fingerprint. Bioglobe’s researchers analyse samples in the lab to determine the dominant pollutant classes—hydrocarbons, phenols, detergents, ammonia, or PFAS precursors—and design a bespoke cocktail of enzymes optimised for those contaminants.

The enzymes work effectively under both aerobic and anaerobic conditions, which means they can be applied in lagoon systems, reactors, or directly within collection tanks. They are particularly efficient at reducing:

- Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD)

- Hydrocarbon residues

- Ammonia and nitrogenous compounds

- Odours and surfactant foams

The result is a cleaner, less reactive liquid that can safely proceed to downstream treatment without overwhelming existing infrastructure.

Building the Pre‑Treatment Train

To protect sewers, rivers, and farmland, leachate must be treated at or near its source—before blending with municipal sewage. The proposed “Safer Leachate Pathway” achieves this through a stepwise pre‑treatment train.

Step 1: Enzymatic Breakdown of Organics

In the first stage, Bioglobe’s customised enzyme blend is introduced into the raw leachate. The enzymes catalyse the degradation of biodegradable organics, oils, greases, and surfactants. This process significantly lowers COD and stabilises the liquid by removing reactive components that can destabilise biological systems.

During this stage, the enzymes also initiate partial hydrolysis of longer‑chain organic compounds, producing smaller molecules that are more readily adsorbed or oxidised in later stages.

Step 2: Adsorption of Persistent Chemicals

After enzymatic treatment, the liquid is filtered through an adsorption medium such as activated carbon, zeolite, or biochar. These materials have large surface areas that trap PFAS molecules, solvents, and heavy metals.

Using organic or mineral adsorbents ensures that no secondary pollutants are created. The spent adsorbent can be replaced and regenerated safely.

Step 3: Oxidation and Polishing

For residual persistent chemicals, advanced oxidation processes—such as electrochemical or photocatalytic oxidation—can be applied. These treatments, combined with enzyme pre‑conditioning, enhance the complete destruction of PFAS precursors without excessive energy use.

The result is a clarified effluent, free from the majority of biodegradable and toxic substances, ready for final polishing or safe discharge under permit.

Step 4: Nutrient Balance and Re‑use

Depending on the site’s configuration, treated effluent can be recirculated within the landfill for moisture management, reducing the overall volume requiring external disposal. The remaining solids, now stabilised and non‑toxic, may be processed into biomass suitable for energy recovery.

Performance Benefits

The Safer Leachate Pathway delivers multiple measurable benefits compared with traditional chemical or purely biological methods:

- Reduced sludge generation

Enzymes convert complex organics into water‑soluble substances, greatly reducing sludge production and disposal costs. - Improved downstream plant stability

By lowering ammonia and COD before entering sewer systems, load shocks to municipal wastewater plants are minimised, preventing microbial inhibition. - High pollutant removal efficiency

Laboratory and on‑site results have demonstrated significant reductions in PFAS precursors, hydrocarbons, and other organics when enzyme treatment precedes adsorption and oxidation. - Safety for ecosystems

Every ingredient in Bioglobe’s products is environmentally benign. The process avoids chlorine, acids, or synthetic reagents that could generate secondary toxins. - Adaptability

The enzyme blends can be reformulated for differing conditions—high salinity, temperature, or pH—making them suitable for both new and historic landfill sites. - Cost‑effectiveness

The approach requires only modest infrastructure, minimal energy, and no hazardous waste disposal. Operating costs are typically lower than conventional physico‑chemical treatment systems.

Towards Measurable KPIs

For landfill operators, councils, or water utilities, pilot projects can be established to verify performance under UK conditions. The key indicators for evaluation can include:

- Percentage reduction in COD and BOD – A target of more than 70 per cent reduction within 24‑48 hours of enzyme exposure.

- Ammonia and Total Nitrogen removal – Improved nitrogen balance through conversion of ammonia to harmless nitrogen gas.

- PFAS or persistent pollutant decrease – Mass‑balanced analysis to confirm retention or destruction through adsorption and oxidation.

- Sludge volume and toxicity tests – Measurement of reductions in heavy metal bioavailability and improved biosolid suitability for agricultural reuse.

- Energy and cost savings – Comparisons with standard leachate transport and treatment charges.

These KPIs offer a transparent, data‑driven foundation for scaling up treatment at a regional or national level.

Environmental Integrity and Ecosystem Safety

Perhaps the most valuable feature of Bioglobe’s approach is its environmental compatibility. Conventional chemical treatments often achieve pollutant reduction at the expense of secondary contamination. Many use oxidants, acids, or flocculants that produce toxic residues. Bioglobe’s enzyme formulations, by contrast, operate within the same biochemical framework as natural decomposition.

When the enzymes finish their work, they degrade into amino acids and proteins readily digested by native microbial communities. The process mimics natural bioremediation, only accelerated and directed with scientific precision. It does not harm fish, aquatic plants, or soil organisms. Laboratory trials have shown that treated effluent can sustain aquatic life without stress or oxygen depletion.

The concept represents a shift from reaction‑based treatment to harmony‑based restoration—solving pollution through organic chemistry that complements the environment rather than challenges it.

Addressing PFAS – The Forever Challenge

PFAS contamination represents one of the most persistent environmental problems of the twenty‑first century. Conventional wastewater systems, even those using advanced membranes, often fail to remove these compounds because of their exceptionally strong carbon‑fluorine bonds.

Recent research has shown that biological and chemical oxidation processes in landfill and wastewater treatment can actually form new PFAS from precursor molecules. This means that some treatment strategies amplify rather than neutralise the problem.

Bioglobe’s method tackles this challenge by reducing the precursor load at the earliest stage. Many PFAS compounds are created through the degradation of larger molecules like fluorotelomer alcohols. Enzymatic oxidation and hydrolysis can target those precursors, preventing their conversion into harmful PFAS forms further downstream.

When combined with selective adsorption and controlled oxidation, the result is a substantial reduction in the overall PFAS mass balance before wastewater reaches the environment. This layered approach not only lowers concentration levels but interrupts the chemical pathways that perpetuate contamination.

How the System Integrates into Existing Infrastructure

The pre‑treatment train can be deployed flexibly to suit different landfill or industrial sites. For many operators, the existing leachate collection systems already feed into balancing tanks or lagoons. Bioglobe’s enzymes can be dosed directly into these systems with automatic feed units that monitor pH, temperature, and flow.

For higher efficiency, a modular treatment skid can be added, containing adsorption and oxidation units. These modules require minimal energy input and can operate under variable flow conditions. Treated water can be discharged to a sewer under consent or recirculated within the site for dust suppression or compaction, depending on local regulations.

The technology does not require high pressure, complex membranes, or specialist operators, making it simple to retrofit at existing installations.

Social and Economic Impacts

Beyond the immediate environmental gains, safer leachate treatment has broader social and economic benefits. Clean water underpins public confidence, agricultural quality, and biodiversity. When toxic loadings on rivers and soils fall, local ecosystems recover more quickly; aquatic life returns and recreational water quality improves.

Reducing PFAS discharge also protects future generations from chronic exposure risks that have long‑term public health implications. For landfill operators and local authorities, adopting sustainable treatment technologies can reduce regulatory penalties and enhance community reputation.

Bioglobe’s solutions are often more affordable than chemical alternatives. They minimise the need for hazardous chemical storage, complex permits, and costly sludge disposal. The economic benefit lies in lower running costs and in the reduced environmental liability associated with persistent pollution.

From Leachate to Livability – A Vision for the Future

The story of landfill leachate is, fundamentally, a story about how we manage the legacies of industrial and consumer society. Buried waste does not disappear; it changes form. By addressing leachate at its source, we prevent yesterday’s pollution from becoming tomorrow’s contamination.

A national framework of “Safer Leachate Pathways” could see local waste management transformed into a system that actively restores rather than damages ecosystems. Pilot schemes can build transparent evidence: measurable KPIs, independent verification, and cost‑benefit analyses. In time, such programmes could be integrated into regional environmental strategies, supporting the UK’s goals for river improvement, biodiversity recovery, and a circular economy.

For Bioglobe, the mission extends beyond landfill management. The same enzyme science supports remediation of contaminated soils, industrial effluent, crude‑oil residues, and urban water bodies. Each success story reinforces the principle that sustainable remediation can be both effective and ecologically kind.

Bioglobe’s Commitment to Sustainability

Bioglobe operates on three fundamental principles—innovation, environmental harmony, and measurable impact. The company’s research and development centre in Larnaca, Cyprus, produces and tests enzyme blends for multiple industrial and environmental applications. Every formulation is plant‑derived, biodegradable, and produced under strict quality control.

The UK division of Bioglobe continues to expand partnerships with councils, environmental engineers, and wastewater utilities to bring these innovations into mainstream use. The approach is deeply collaborative: rather than replacing existing infrastructure, Bioglobe works with operators to enhance performance using biological methods that respect and complement the natural environment.

Public Awareness and Education

Environmental technology can only succeed when people understand and trust it. Many members of the public hear the term “leachate” and imagine a distant, industrial process with little relevance to everyday life. Yet the same pollutants in that leachate can reappear indirectly in drinking water, food, and ecosystems.

Educational initiatives are essential to help communities grasp that pollution management is not just about compliance—it’s about long‑term ecological security. Bioglobe encourages transparent communication about treatment outcomes, using measurable scientific data to demonstrate how enzyme‑based solutions eliminate harmful compounds safely.

By showing that organic, nature‑based remediation works both efficiently and harmlessly, the public can see sustainability not as a cost but as a strength and necessity.

Demonstrating the Problem, Consequences, and Solution

Problem:

Toxic landfill leachate, rich in PFAS and other persistent chemicals, is being blended with sewage in treatment works that cannot remove or neutralise these substances.

Consequences:

These pollutants pass into rivers and seas, accumulate in agricultural soil through sludge reuse, and re‑enter the food chain. They disrupt wastewater treatment operations, harm aquatic life, reduce water quality, and increase long‑term health risks to humans.

Solution:

Bioglobe’s Organic Enzyme Remediation System pre‑treats leachate before it enters the sewer. Customised enzyme formulations break down degradable organics, reduce ammonia and COD, and prepare the liquid for adsorption and oxidation of PFAS. The process is cost‑effective, fully biodegradable, and safe for ecosystems, creating a closed‑loop cycle that eliminates pollution without creating new problems.

A Path to Cleaner Water and Resilient Ecosystems

Implementing safer leachate pathways is not simply a technical challenge but a societal choice. It represents a shift toward stewardship—accepting responsibility for the hidden outputs of everyday consumption. Every modern product, from T‑shirts to frying pans, leaves invisible chemical traces, many of which find their way into the wastes buried beneath us. By tackling leachate organically, using the most powerful tools of biology itself, we can halt that cycle.

As the environmental pressures of climate change increase—bringing heavier rainfall and rising groundwater levels—the urgency of managing landfill leachate safely grows stronger. Bioglobe’s organic enzymatic solutions offer a way forward that is scientifically credible, ecologically sound, and economically viable.

They do not ask nature to adapt to our processes; they design processes that adapt to nature.

Frequently Asked Questions

1. What exactly is landfill leachate?

Leachate is the liquid that forms when water filters through waste material in a landfill. It carries dissolved and suspended contaminants including organic matter, ammonia, metals, plastics, and chemicals such as PFAS. Every landfill produces a different type of leachate depending on what waste it contains and how old it is.

2. Why is landfill leachate mixed with sewage?

Many older waste management systems lack dedicated leachate treatment facilities. Sending the liquid to sewage treatment works was historically considered a convenient solution because those plants already handled wastewater. However, they were not designed for difficult industrial pollutants and cannot remove many of the harmful compounds now present.

3. What are PFAS and why are they dangerous?

PFAS stands for per‑ and polyfluoroalkyl substances. They are synthetic chemicals used to make products water‑ or grease‑resistant. Unfortunately, their carbon‑fluorine bonds are incredibly strong, making them persistent in the environment. PFAS have been linked to health issues such as thyroid disorders, immune suppression, and developmental effects, and they do not naturally degrade in soil or water.

4. How do enzymes clean the leachate?

Enzymes act as catalysts that accelerate natural breakdown reactions. When added to leachate, they target specific molecules like hydrocarbons, proteins, or sugars and transform them into harmless components that dissolve or gasify. Bioglobe’s plant‑based enzyme blends are designed to act quickly even in harsh conditions, drastically reducing pollutant loads without producing secondary contamination.

5. Are Bioglobe’s enzyme products safe for wildlife and the environment?

Yes. They are entirely organic and biodegradable. After completing their task, the enzymes themselves break down into natural amino acids and nutrients. They have been tested in aquatic conditions and shown to be non‑toxic to fish and plants. No corrosive chemicals or residues remain.

6. Can this technology help older, closed landfills?

Absolutely. Many historic sites still generate leachate decades after closure. Bioglobe’s modular system can be adapted for these low‑flow sites, offering an affordable, low‑maintenance solution for long‑term pollution control.

7. How quickly does it work?

Initial pollutant reductions typically occur within the first 24 to 48 hours after treatment begins. Complete stabilisation varies depending on the leachate composition and site conditions, but the system continues to perform consistently once established.

8. Is the process expensive?

Compared with conventional chemical oxidation or membrane filtration, enzyme treatment is significantly more economical. It uses far less energy, generates no hazardous waste, and extends the life of downstream plant equipment. Long‑term savings come from reduced sludge, fewer transport costs, and better compliance.

9. Can it be integrated with existing wastewater infrastructure?

Yes. The enzyme systems can be installed as pre‑treatment units at the landfill site or upstream of a sewage intake. They complement rather than replace existing systems, improving their efficiency and reducing operational stress.

10. What makes this approach different from other “green” technologies?

Bioglobe’s technology combines modern enzymology with precise analytical testing. Rather than applying a generic biological treatment, each enzyme blend is uniquely formulated after laboratory analysis of the pollutants concerned. This targeted design maximises breakdown efficiency while remaining completely natural.

Conclusion

The pollution challenges Britain faces today are not inevitable; they are residues of past convenience and technological limitation. The landfill leachate issue, in particular, demands thoughtful innovation that respects ecological boundaries while protecting human health.

Bioglobe’s organic enzyme remediation solutions demonstrate that advanced science and environmental kindness can coexist. Through a tailored, natural process, they make it possible to transform harmful leachate into a manageable, non‑toxic effluent—without introducing new hazards.

The transition to safer leachate pathways is both an environmental imperative and an opportunity for leadership. By adopting organic enzymatic pre‑treatment, landfill operators, councils, and water utilities can take measurable steps towards cleaner rivers, sustainable agriculture, and healthier communities.

In the end, leachate management is about more than engineering. It is about how we choose to coexist with the materials and by‑products of modern life. With the right tools—those that nature itself has provided—we can correct the course and ensure that the water beneath our feet remains pure for generations to come.

Bioglobe offer Organic Enzyme pollution remediation for major oil-spills, oceans and coastal waters, marinas and inland water, sewage and nitrate remediation and agriculture and brown-field sites, throughout the UK and Europe.

We have created our own Enzyme based bioremediation in our own laboratory in Cyprus and we are able to create bespoke variants for maximum efficacy.

Our team are able to identify the pollution, we then assess the problem, conduct site tests and send samples to our lab where we can create a bespoke variant, we then conduct a pilot test and proceed from there.

Our Enzyme solutions are available around the world, remediation pollution organically without any harm to the ecosystem.

For further information:

BioGlobe LTD (UK),

Phone: +44(0) 116 4736303| Email: info@bioglobe.co.uk